The Essence of Arti

Arti embodies a unique blend of meanings across cultures, symbolizing our commitment to innovation in agriculture. In Georgian, ერთი signifies the number one, reflecting our goal to lead in sustainable practices. The Arabic interpretation, ارتوئ, emphasizes our mission to fulfill essential needs, while the Turkish term Arti translates to ‘plus’, representing our aim to enhance food production with renewable energy. At Arti, we believe that our advanced production methods and technologies are the bedrock of success, enabling us to feed and satisfy the world as it is in our name.

Revolutionize and Energy

Discover Our Vision and Values

Harnessing the Power of Agri-voltaic Innovation

Explore our recent projects where we have successfully implemented biomass energy solutions. From Indonesia to Vietnam, our innovative approaches have optimized energy structures and ensured stable energy supply.

We have developed a pyrolysis solution to process hazelnut shells at an annual output of 12.4 GWh electricity, 9,375 tons of Biochar, 1,875 tons of wood tar, 5,625 tons of wood vinegar tri-production line at an investment outlay of US$3.7M.

Indonesia Biomass Project

Vietnam Retrofit Success

Comprehensive Hydrogen Energy Approach

Explore our integrated approach to hydrogen energy, encompassing complete vehicle manufacturing, a robust industry chain, an energy supply network, carbon management and an operation platform.

Complete Vehicle Manufacturing

Innovative solutions for manufacturing vehicles powered by hydrogen fuel cells.

Industry Chain

Upstream and downstream integration of the fuel cell industry chain.

Energy Supply Network

An integrated network ensuring efficient hydrogen energy distribution.

Carbon Management

Advanced carbon assets and big data management and operation centre.

Operation Platform

A comprehensive platform for hydrogen energy operations.

Explore our advanced vanadium battery systems designed for various energy storage needs from household to industrial applications

Project 1:

Located in the Energy Storage Industrial Park, this project boasts a capacity of 2MW 8MWH. Completed on January 8, 2024, it was developed for Hebei Jiantou Vanasheng Energy Storage Technology Co., Ltd.

Project 2:

This ambitious project, with a capacity of 10MW 40MWH, is set in the same industrial park and was delivered in April 2025 for Zhongjing Construction Group Co., Ltd.

Revolutionizing Crop Management with Smart Solutions

Arti is at the forefront of transforming agriculture with intelligent, digital, and unmanned management systems for grain crops like ice, wheat, corn, and cotton. Our solutions enhance field management efficiency, reduce costs, and improve yield and quality, ultimately increasing income for farmers.

By integrating the application of modern agricultural information technologies such as the new generation of Internet of Things, big data, artificial intelligence, and unmanned driving, we aim to build a smart farm with high standard agronomy as the guarantee, intelligent agricultural machinery as the core, precision cultivation as the means, and comprehensive farm management big data platform as the support. We aim to achieve a reliable perception, comprehensive interconnection, and digital intelligent control of the farm, and achieve the transformation from traditional manual control to remote wireless intelligent control, Improve the decision-making ability of agricultural production management.

65 ha agricultural production of mixed farm will be farmed as raw material for cold tea brew production: primarily mint + other small test production of other fruits, vegetables and herbs (4ha) + animal feed in goat and fish farming: corn (19 ha) + wheat (42 ha) based on average CAPEX US$ 20k per ha and OPEX us$ 10k per ha based on benchmark numbers including Smart farm solutions including software + hardware machinery used in previous smart farm agricultural projects in China and Malaysia from an investment outlay of US$1.3 M.

Intelligent Machinery Control

Our advanced systems enable precise control of agricultural machinery, ensuring optimal performance from sowing to harvesting.

Digital Infrastructure

We provide a robust digital agricultural infrastructure that supports seamless integration of various technologies for efficient farm management.

IoT Technology

Our IoT solutions offer real-time dynamic monitoring of soil moisture, pest conditions, climate, and seedling health, enabling precise crop management.

At Arti, we are revolutionizing the hazelnut industry by converting low-value in-shell hazelnuts into high-value roasted hazelnuts and organic fertilizer. Our innovative process utilizes hazelnut shells, animal, and plant waste to produce biochar through pyrolysis, offering an effective waste management solution. This 100% organic fertilizer not only supports agronomic use but also contributes to carbon neutrality, providing both economic and environmental benefits.

Our Continuous Hazelnuts Roasting Machine is equipped with the technological progress of enterprise performance, product technology to improve the hazelnut roaster cooler machine has been to meet the large production, diversification, centralized control, continuous production capacity, widely used for processing peanut, almond, walnut, cashew nuts and sunflower seeds.

Our Organic Fertiliser production system includes Extrusion, Granulation, Drying, Mechanical & Accessories and the design and construction of fertiliser engineering are powered by cutting-edge technologies with engineering excellence.

We have developed a 950 tons of hazelnut and 3,040 tons of organic fertiliser within integrated hazelnut + organic fertiliser annual production system. Hazelnut shell waste to be used as raw material input in biochar production at an investment outlay of US$2.1M.

Discover how Arti is revolutionizing beekeeping with a digitalized sanctuary network. Our innovative approach safeguards bee-hives, supporting 70% of the world’s plants by preserving local bee varieties. Join us in creating a sustainable future with AI and IoT technology.

Mapping the Future of Beekeeping

Discover our innovative in-land aquaculture farming system that integrates indoor, smart, vertical farming hydroponics for raw material production of fish feed. Our re-circulatory aquaculture system (RAS) is designed to transform traditional aquaculture into a modern, efficient, and sustainable practice, addressing bio-security and geo-climatic concerns.

We have developed a 170 tons of rainbow trout within integrated rainbow trout and animal feed production system at an investment outlay of US$2.5M.

Smart Aquaculture System

Key Benefits

Efficient use of space and water, improving fish health, and supporting sustainable fish farming are important goals in today's aquaculture. The recirculating aquaculture system (RAS) is modernizing traditional fish farming, allowing for more variety and better integration in the industry, which can lead to new business opportunities. RAS is effective because it uses much less space and water. Today's fish farming faces challenges like sustainability, health risks, and climate change. Therefore, adopting new technologies like RAS is essential for producing high-quality fish while conserving water. This innovative method has been successfully used in many countries. **Less Water:** RAS systems use 90% less water than traditional methods by recycling most of their water. This makes them suitable for areas with limited water resources. Typically, RAS farms only replace 5 to 10% of their water daily for cleaning purposes and to account for evaporation. **Less Space:** RAS systems take up much less land because they allow for higher fish stocking densities. In traditional ponds, fish density can exceed 80 kg/m³, enabling RAS farms to be established in areas with not enough flat land for ponds. **Controlled Water Temperature:** Another advantage of RAS is the ability to control water temperature. With lower water needs, farmers can manage the water temperature and growth rates of fish, allowing them to raise species that usually wouldn’t thrive in certain regions. This control helps maximize feed efficiency and ensures optimal growth year-round, increasing production and speeding up product turnover. **Real-Time Monitoring:** RAS systems excel in water quality control. By keeping dissolved oxygen levels optimal, this technology ensures better feed efficiency, reduced stress on fish, improved disease resistance, less food waste, and faster growth. It allows for real-time monitoring and adjustments through on-site controls, remote access, or mobile devices. **Environmental Advantages:** RAS systems are more environmentally friendly because they produce very little waste and have controlled waste discharge. Nearly all water used in the system is recycled, leading to less waste compared to traditional methods.

Identify ideal areas in for goat farms, improve farm productivity and enhance services supporting the goat farming sector. Herd management tools connect with the most modern sensor technologies and through intelligent functions make them accessible for milk farmers. Discover ways of managing dairy farms efficiently. Herd Management system filters information to provide the streamlined perspective you need for the typical tasks at a dairy farm. With complete life histories you can get to know each goat better and keep track of her from birth on, even when the herd grows. Whether it’s current milk performance, cell count class analysis per udder quarter, measuring activity or oestrous behaviour – early signs and health alerts help you target your response. You reduce milk losses, save treatment costs and improve reproduction performance and goat birth intervals.

Rapid Exit Small Ruminant Parlour for goats is one of the quickest milking parlours in terms of animals milked per hour thanks to efficient entry and exit design, the SR Rapid Exit excels at milking small ruminant animals. Animals are quickly and safely guided into the milking parlour, where individual indexing gates align animals to the ideal milking presentation.

We have developed a 2,000 goat herd farming facilities at 160 tons of goat’s cheese annual production in 1st year forecast to increase 70% year on year through to 2035 at an investment outlay of US$5M.

Key Benefits

Boost local economies, create jobs, and enhance food security through innovative goat farming practices. Implement inclusive market projects by supporting the setup of goat farms in underdeveloped rural areas. Connect these farms to potential market channels and sales opportunities, creating employment for the poor, especially returnees and those in the poorest regions.

Discover how our honey, mint, and black tea-based cold tea production transforms low value-add agricultural products into high value-add beverages, boosting the local economy.

We have developed a 15.2 M units of 500ml pet bottle fruit-based, sugar-free, cold-tea brew annual production at an investment outlay of US$1.5M.

Our Portfolio

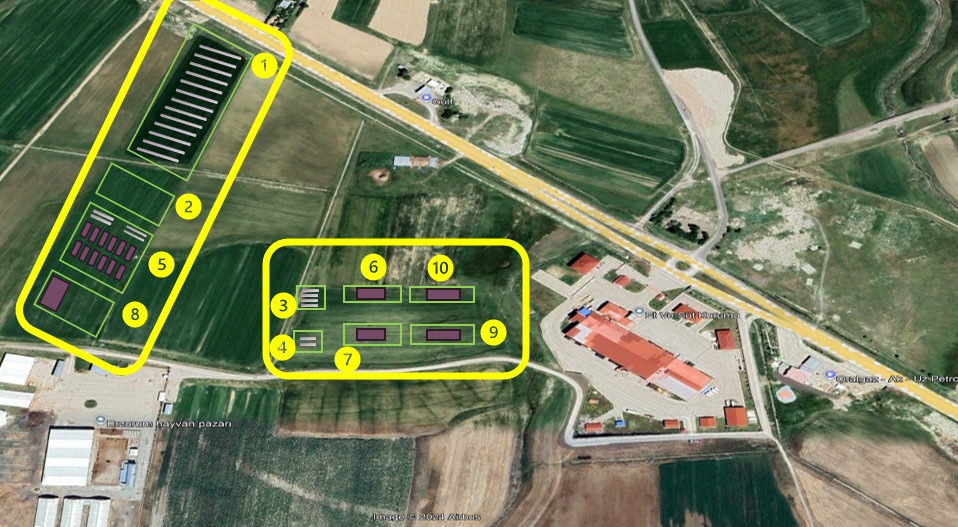

Land Development Plan for our Agri-voltaic, Energy Storage Systems and Waste Management project over 124 Ha

Explore our prime land offerings designed for agri-voltaic projects, integrating renewable energy with sustainable agriculture.

Erzurum, Türkiye: All fields amount to a total surface area of 124,000 m², strategically located near the Meat and Fish Association, with easy access to major roads. This site is perfect for integrating energy storage and waste management systems, enhancing agricultural productivity.

Vertical mounting system: corn + wheat field used for animal feed over 46ha : This is a row of 40 panels, with 21 rows in total, amounting to 840 panels and a capacity of 604.8 kW. The land area required is 100 meters by 51.3 meters. For 46 hectares of land, approximately 86 systems can be installed, totaling around 52 MW.

Traditional farm over 15 ha : Plot no 2 will be a traditional wheat + corn field that will be used as a cost and performance benchmark against agri-voltaic food + energy production system in plot no 1.

30% shade rate agri-voltaic farm over 2 ha for mint used in cold tea brew beverages. Module size: 2384*1303*35mm

Module layout: 14X20, 14 units, horizontal Module quanity: 3920 pcs, Capacity: 2.8224MW. Production of Other herbs, kale, lettuce, salad greens, spinach, beans, beet, broccoli, carrots, cauliflower, hot/chilli peppers, peas, melons, tomatoes, potatoes, corn, egg plant and okra can be tested here.

50% shade rate agri-voltaic farm over 2 ha for mint used in cold tea brew beverages. Module size: 2384*1303*35mm

Module layout: 14X20, 16 units, horizontal Module quanity: 4480 pcs, Capacity: 3.2256MW. Production of Other herbs, kale, lettuce, salad greens, spinach, beans, beet, broccoli, carrots, cauliflower, hot/chilli peppers, peas, melons, tomatoes, potatoes, corn, egg plant and okra can be tested here.

27 Apiary stations hosting 6,015 bee hives over 30 ha. Bee hives will be moved to locations to improve cross-pollination. Managing solar farms for wild pollinators also delivers many other ecological benefits. 30% shade rate pv-apiary farm over 2 ha and 50% shade rate pv-apiary farm over 2 ha.

Integrated Roasted hazelnut + organic fertiliser + cold tea beverage production factory has 3 production areas: Organic fertiliser, roasted hazelnuts and cold tea beverage, cold storage area, common hallway and mezzanine floor for admin work over 0.5 ha.

Integrated in-land aquaculture farming system including Indoor, smart, vertical farming hydroponics system for raw material production of fish feed, fish feed production and rainbow trout production over 0.4 ha.

Goat farming and goat’s cheese production 10 x 200 goat farms and goat’s cheese production over 10 ha.

Pyrolysis production line 9,375 tons of Biochar, 1,875 tons of wood tar, 5,625 tons of wood vinegar tri-production line from hazelnut shells over 0.4 ha.

Vanadium redox flow battery production line has the capacity to integrate and assemble up to 25 battery units at 1mw, 5mw, 10mw scale annually over 0.2 ha.

Our Portfolio

Innovative Project Insights

Explore our ground-breaking projects that merge food production with renewable energy, ensuring a closed-loop, localised and re-generative farming system.

Our business plans are forecast to deliver a 10-year NPV of $ 120 M from an initial investment outlay of $ 70 M. The results of financial model indicates that opting for project development is an attractive business investment, giving a positive 10-year NPV of $120 M, high IRR of 38% and an appropriate payback period of 5 years.

Financial Highlights

- IRR: 38%

- WACC: 17.5%

- NPV (10 year basis): $ 120 million

- Investment Outlay: $70 million

- Payback Period: 5 years based on single company owner

- Payback Period: 10 years between 2 partners of equal company share size after profit payout

- Payback Period: 15 years between 3 partners of equal company share size after profit payout

Discover the Benefits of Agri-voltaics

Maximized Land Use Efficiency

Enhanced Crop Yield

Reduced Operational Costs

What Our Clients Say

Contact Remzi Yavuz

For inquiries regarding our Agri-voltaic solutions, please reach out to Remzi Yavuz, CEO of Arti. You can contact him via email at artivoltaic@gmail.com or call him at +90 530 099 0792 or +44 7776 969309. He is dedicated to providing you with the information you need.

Contact Mohammed Effendy

For technology-related inquiries, please contact Mohammed Effendy, Head of Technology. He can be reached at agropvintegrated@gmail.com or by phone at +60 19678 7178. Mohammed is eager to discuss our innovative Agri-voltaic systems with you.

Visit Us

We welcome you to visit our facilities are located across Turkiye, Malaysia and the United Kingdom. Our operational office is located at 08490 Camili, Borçka, Artvin, Türkiye.

Additionally, our technology team headed by Mohammed Effendy is based at Hybrid AgriVoltaic system (HAVs), Fakulti Kejuruteraan, Universiti Putra Malaysia (UPM), 43400 Serdang, Selangor, Malaysia.

Our Business Development Team headed by Anwar Shah is based in London, United Kingdom. He can be reached at +44 734 235 2071. Feel free reach out to him and learn more about our projects.

Our Strategic Partnerships

At Arti, we collaborate with industry leaders to enhance our agri-voltaic, energy storage and waste management solutions. These partnerships enable us to integrate cutting-edge technology and sustainable practices, ensuring the success and scalability of our projects.

Mabiyoder is the sole representative for the only declared “bio-sphere reserve area called Macahel” based in Artvin, Türkiye within the scope of UNESCO’s man and biosphere programme. Mabiyoder focuses it’s activities on sustainable beekeeping and honey production.

SINJI has the international leading level of patented technology and important achievements in high performance perfluorinated ion membrane for vanadium batteries based in China.

Landscape Photovoltaic Storage Integration System is a brand-new structure energy storage, and its basic function is organically combined with environment and landscape.

The system adopts photovoltaic power generation and all-vanadium liquid current battery energy storage, and has the utility complementary function, can be widely used in industrial parks and urban landscape lighting.

UPM specialises in Agri-voltaic technology for solar PV farms based in Malaysia. We are the service provider for Agri-voltaic Integrated solutions with the aims to reduce maintenance cost on ground vegetation, optimising solar farm space with agricultural activities and reducing potential risks in LSS (large-scale solar) operations. We provide service for Weed Maintenance in solar farms and at the same time creating Agri-voltaic space for cash crops cultivation.

HaiQi is an innovation enterprise specialising in the replacement of fossil energy by biomass gas clean energy, and a national high-tech enterprise based in China.

Mainly engaged in the research and development, production and promotion of semi-gasification biomass burners, biomass gasifiers, waste recycling and containerised distributed power plants.

As a mature system, Biomass Gasification Power Plant has realised continuous and factory production with high efficiency, cleanliness and zero pollution.

One Point | Complete vehicle manufacturing

One Line | Upstream and downstream industry chain of fuel cell

One Network | Integrated energy supply network

One Centre丨Carbon assets and big data management and operation centre

One Platform | Hydrogen energy operation platform